About Leaf And Grain

The agricultural sector is a critical component of the economy, providing food and employment for millions. However, the use of pesticides and other chemicals poses a significant risk to health and safety. This project focuses on the packaging and processing of grains, fruits, and vegetables to ensure that products are not only safe for consumption but also retain their nutritional quality.

Importance of Packaging and Processing

Effective packaging and processing can significantly extend the shelf life of agricultural products, reduce spoilage, and maintain quality. This project emphasizes the ozonization process, which helps eliminate harmful residues from pesticides and arsenic before packaging.

• Minimal processing results in the least change in the chemicals of food, provide the highest quality and result in foods with a very short shelf-life.

• As processing is performed to extend shelf-life (drying,canning), there is more chemical change and loss of perceived quality.

Why Choose Leaf And Grain

Here’s a breakdown of the benefits for various stakeholders in your fruit and vegetable processing project, both individually and for society:

I. Farmers (AOP Partners)

● Individual Benefits:

○ Stable Income: Guaranteed market for their produce, reducing risk and ensuring a more predictable income stream.

○ Access to Technology & Training: Opportunities to learn improved farming techniques, potentially leading to higher yields and better quality produce.

○ Reduced Post-Harvest Losses: Processing reduces spoilage, maximizing the value of their crops.

○ Empowerment: Direct involvement in the value chain, increasing their bargaining power.

● Societal Benefits:

○ Increased Agricultural Productivity: Adoption of better farming practices can boost overall agricultural output in the region.

○ Rural Development: Improved livelihoods for farmers can contribute to the economic development of rural communities.

○ Food Security: Increased availability of processed fruits and vegetables contributes to local food security.

II. Women in Self-Help Groups (SHGs)

● Individual Benefits:

○ Employment & Income: Gainful employment opportunities and a steady source of income, empowering them financially.

○ Skill Development: Acquire new skills in food processing, packaging, and potentially management, enhancing their employability.

○ Social Empowerment: Working in groups fosters a sense of community and provides a platform for social and economic empowerment.

● Societal Benefits:

○ Women’s Empowerment: Increased economic independence and social participation for women.

○ Community Development: Improved livelihoods for women often translate to better health and education outcomes for their families and communities.

○ Reduced Poverty: Income generation opportunities for women can contribute to poverty reduction in the region.

III. Consumers (Older Individuals/Couples & Young Professionals)

● Individual Benefits:

○ Convenience: Access to ready-to-eat or easy-to-prepare fruit and vegetable products, saving time and effort.

○ Healthier Options: Increased availability of nutritious food options, promoting better health and well-being.

○ Quality & Safety: Processed foods can often ensure higher quality and safety standards compared to open market produce.

○ Variety: Access to a wider variety of fruits and vegetables, even those not locally available year-round.

● Societal Benefits:

○ Improved Public Health: Increased consumption of fruits and vegetables contributes to a healthier population.

○ Reduced Food Waste: Processing extends the shelf life of produce, reducing overall food waste.

Minimal Processing

Key Requirements in the minimal processing of fruit and vegetables:

- Good quality raw materials (correct variety, correct cultivation, harvesting and storage conditions.

- Strict hygiene and good manufacturing practices, use of hazard analysis and critical control point principles.

- Low temperatures during processing.

- Careful cleaning and/or washing before and after peeling.

- Good quality water (sensory, microbiology, pH) for washing.

- Use of mild additives in washing water for disinfect ion for the prevention of browning.

- Gentle spin drying following washing.

- Gentle peeling.

- Gentle cutting, slicing and/or shredding.

- Correct packaging materials and packaging methods.

- Correct temperature and humidity during distribution and retailing.

Cleaning, washing and drying

- 100-200mg of chlorine or citric acid per liter is effective in washing water before or after peeling and/or cutting to extend shelf-life.

- Alternatives to chlorine include chlorine dioxide, peracetic acid ozone, trisodium phosphate and hydrogen peroxide. (cucumbers, bell paper)

Browning inhibition

- Sulphites.

- Pineapple juice (Apple).

- Glycine betaine (Shredded lettuce).

- Ascorbic acid/citric (Potatoes).

- Erythorbic acid, an isomer of ascorbic acid (Potatoes slices).

- A chemical reductant (e.g. ascorbic acid).

- An acidulant (e.g. citric acid).

- A chelating agent (e.g. EDTA).

Hot water blanching

- Traditional form of blanching which involves the product being held in hot water(85-100°C) until the enzymes are inactivated and the water cooled. Its also known as rotary hot water system.

- Blanching is also done by tunnel type system (heating, holding and cooling).

WHAT IS MINIMAL PROCESSING

- Minimally Processed Foods are those which minimally influences the quality characteristic of a food, whist at the same time giving the food sufficient shelf life during storage and distribution.

- Minimally processed technologies are techniques that preserve foods, but also retain to a certain extent their nutritional quality and sensory characteristics by reducing the reliance on heat as the main preservative action.

- Minimally fresh processed fruit and vegetables are prepared for consumption by using light combined methods such as washing, cutting, grating, shredding, pulling the leaves off, etc. and packing at chilling temperatures under polymeric films that are able to generate optimum modified atmosphere packaging (MAP) conditions.It is also named fresh-cut or ready-to-eat, is commonly free from additives and only needs minimal or no further processing prior to consumption (Artés, 1992, 2000a; Artés and Martínez, 1996; Odumeru et al., 1997).

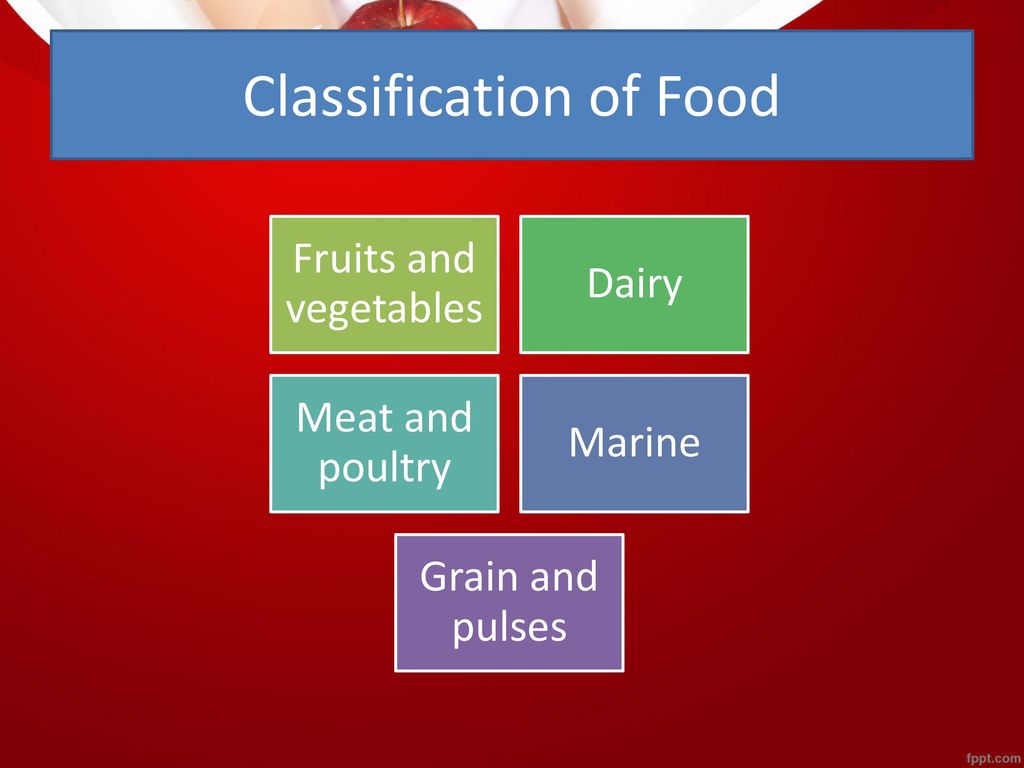

| Processing | Primary | Secondary | Tertiary | |

| Fruits & Vegetables | Cleaning, sorting and cutting | Slices, pulps and paste | Ketchups, jam, juices and pickles | |

| Marine products | Chilling and freezing | Cut, fried, frozen and chilled | Ready-to-eat meals | |

| Grain and seeds | Seeding and grading | Flour, malt and milling | Biscuits, noodles,flakes, cakes, savory | |

| Beverages | Sorting, bleaching and grading | Leaf, dust and powder |

|

|

preparation of minimal processed fruits and vegetables

| Step No. | Process Step | Additional Notes |

| 1 | Harvesting | |

| 2 | Receiving | |

| 3 | Pre-cooling | |

| 4 | Washing and Disinfection | |

| 5 | Peeling, Trimming, and Deseeding | |

| 6 | Cutting to Specific Sizes | |

| 7 | Sorting for Defects | |

| 8 | Dipping | Antimicrobial Agent, Antibrowning Agent |

| 9 | Drying | |

| 10 | Packaging and Labeling | |

| 11 | Storage and Distribution |

Examples

- Shredding of cabbage/ lettuce 2. Shelling of peas

- Snapping of beans

- Grating of carrot

- Cauliflower and broccoli florets

- Sticks of carrot and celery

- Trimmed spinach

- Peeled and sliced potatoes

- Diced onion

- Slices of mango cheeks/ melons/papaya/apple/others

- Pieces of pomelo segments and other citrus fruits

- Peeled and cored pineapple

- Chilled peach

- Pomegranate arils dressing

- Drying of onion, mango lather, grapes, sun dried tomato

- Microwaveable fresh vegetable trays

Primary Processing

Primary processing involves a range of processes to make food safe to eat so that it can be consumed individually or used in the manufacture of other food products. The physical form changes very little.

- Harvesting

- Picking

- Washing

- Grading

- Sorting

- Milling

- Packaging

- Weighing

- Distribution

Minimally processing of raw fruits and vegetables has two (2) purposes

- It is important to keep the produce fresh, yet supply it in a convenient form without losing its nutritional quality.

- The product should have a shelf life sufficient to make its distribution feasible to its intended

consumers.

Advantages of Minimal Processing

- Consumers are increasingly demanding convenient, ready to use and ready to eat fruit and vegetables with a fresh like quality and containing only natural ingredients. They can easily go for meal preparation.

- Delivers fresh like characteristics. Peeled, cut/shredded fruits and vegetables if delivered in time, offer fresh like characters.

- Not only general consumers, the catering industry also wants to purchase fruits and vegetables that are sliced, grated or shredded. This is primarily for the reasons of expense, labour and hygiene.